Modular Design

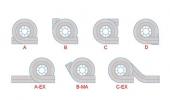

- An innovative modular design allows Ryson to customize with ease and modify in the field to accommodate emerging needs. All spirals are made to order and are available in 4 basic configurations ( A, B, C and D), accommodating most requirements relating to the location of the in and out feed tangents. All configurations can operate up or down in a clockwise or counterclockwise rotation.

- The position of the in feed tangent on up spirals and out feed tangent on down spirals can be customized to meet specific layout requirements. Samples are shown above (A-EX, B-MA and C-EX). A horizontal section is provided at in and out feed to assure smooth transition between conveyors. All Ryson Spirals are available in powder coated carbon steel, stainless steel, washdown, and freezer versions.

Proprietary Chain Slat Arrangement

- This innovative arrangement enables a low friction operation. The slats are supported by precision steel roller bearings which ride on a polyurethane wear surface. This arrangement effectively takes up the side forces created by a tight radius and at the same time increases the load carrying capacity of the chain up to 75 lbs per linear foot. This facilitates high speed, low noise and long life.

Overlapping Slats

- Overlapping slats provide a smooth and efficient conveying surface, suitable for all types of conveyable items. Slat widths of 8, 12, 16, 20, 24 and 26 inches are available. The slats can also be furnished with friction inserts to accommodate slick items such as plastic totes or frozen products.

Built-in Protection

- All Ryson Spirals are equipped with an automatic chain tensioning device and built-in overload protection.

Saving space in your production line has never been easier. The unit load spiral conveyor is an incredibly innovative conveyor that is more reliable and efficient than elevators or lifts. Made-to-order, you can customize your spiral conveyor to suit your layout requirements.

Unit Load Spiral Features:

Small Footprint

- A proprietary low friction chain slat arrangement allows Ryson Spirals to operate within a small footprint, saving valuable floor space.

High Throughput

- The spirals convey loads up or down in a continuous flow, facilitating high throughput. The spirals can operate at speeds up to 200 FPM and are optionally reversible.

One Drive

- Only one drive motor is required, resulting in substantial savings in energy, controls and systems integration.

Easy to Install

- Most spirals are shipped in one piece, pre-assembled and pre-tested, drastically reducing time and cost of installation.

Low Maintenance

- Ryson Spirals are designed for low maintenance and long life. Only high quality components are used throughout. All bearings are sealed for life and need no further lubrication. The chain is of heavy duty nickel plated construction and needs only infrequent lubrication. The slats need no maintenance and can easily be replaced as single components without the use of special tools.

Controls and Integration

- Most of our spirals are shipped without controls because they normally integrate with an overall conveyor control system. The spirals always include an inverter duty gear motor and two proximity sensors, one for the automatic chain tensioner and one for the overload protection device. A Variable Frequency Drive (VFD) is required for proper operation of the spirals.