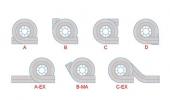

Standard Configurations

- The high capacity spirals are available in 4 basic standard configurations (A, B, C and D) and will accommodate most requirements relating to the location of the in and out feed tangents. All configurations can operate up or down in a clockwise or counterclockwise rotation.

Custom Configurations

The position of the infeed tangent on up spirals and the outfeed tangent on down spirals can be customized to meet specific lay-out requirements. This is possible for all standard configurations.

- C-EX configuration matches the centerline of the top and bottom conveyor centerlines. Centerline offsets can also be accommodated.

- B-MA is an example of modified in or outfeed angle. The modified angle is normally 45 or 30 degrees, but other angles can be provided.

- A-EX show extended in or outfeed tangents which can be straight or curved and can accommodate centerline off-sets.

Able to handle double the capacity of the regular unit load spiral, get your production line moving even more efficiently with a High Capacity Spiral. With a capacity of 75 lbs per linear foot, this machine is built to move, and is able to run at speeds up to 200 FPM. Save on space, time, and production costs with the convenient, all-in-one solution.

High Capacity Spiral Features:

Modular Design

- An innovative modular design allows Ryson to customize with ease and modify in the field to accommodate emerging needs. All spirals are made to order and are available in 4 basic configurations ( A, B, C and D), accommodating most requirements relating to the location of the in and out feed tangents. All configurations can operate up or down in a clockwise or counterclockwise rotation.

- The position of the in feed tangent on up spirals and out feed tangent on down spirals can be customized to meet specific layout requirements. Samples are shown above (A-EX, B-MA and C-EX). A horizontal section is provided at in and out feed to assure smooth transition between conveyors. All Ryson Spirals are available in powder coated carbon steel, stainless steel, washdown, and freezer versions.

Controls and Integration

- Most of our spirals are shipped without controls because they normally integrate with an overall conveyor control system. The spirals always include an inverter duty gear motor and two proximity sensors, one for the automatic chain tensioner and one for the overload protection device. A Variable Frequency Drive (VFD) is required for proper operation of the spirals.

Drive

A Variable Frequency Drive (VFD) is required for the proper operation of the spiral. We offer several controls options including:

- Stand alone control panel with interface capabilities

- Prewired motor disconnect

- Proximity sensors prewired to a central junction box

- Prewired missing slat detection sensors.