Features:

- Straight belts for most general conveying needs

- Radius belts for applications requiring conveyance around curves

- Chains are available in industry-standard widths: 3.25" / 83 mm; 4.5" / 114 mm; 7.5" / 191 mm; and 3.35" / 85 mm.

Belt Styles

- Flat Top: suitable for a wide range of products, when a fully closed belt surface is preferred

- Flush Grid: commonly used in applications where drainage or airflow is desired

- Raised Rib: recommended in applications where product stability over transfers is a concern

- Open Hinge: the most cleanable style of Intralox belting; used where sanitation and hygiene are a primary concern

- Friction Top: commonly employed on incline conveyors, where the elevation of product changes

- Roller Top: used in a variety of low-pressure accumulation applications

- Perforated Flat Top: used when air flow and water flow are critical but the percentage of belt open area must remain low

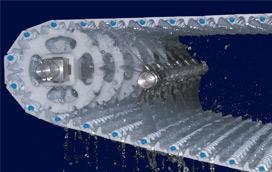

From the inventors of modular plastic belting, Intralox supplies us with a great innovative plastic belt conveying solution. Able to handle high temperatures and run at great speeds, these interlocking plastic belts can handle many different types of tasks efficiently. Easy to clean, and corrosion resistant, these belts are easy to maintain and have great longevity.

Modular Plastic Belt Conveyor Materials:

- Electrically Conductive (EC) Acetal

- High Strength Electrically Conductive (HSEC) Acetal

- Heat Resistant (HR) Nylon

- Impact Resistant (IR) Nylon

- Abrasion Resistant (AR) Nylon

- Flame Retardant Thermoplastic Polyester (FR-TPES)

- Polypropylene Composite (PPC)

- Detectable Polypropylene

- X-ray Detectable Acetal

- High Speed Intralon™

- Enduralox™ Polypropylene

Belt Materials

- Mesh Top

- Non Skid

- Open Grid

- Mini Rib

- Nub Top™ (anti-stick)

- Cone Top™ (extra grip)

- Open Hinge