Ideal For:

- Ensuring high singulation accuracy rates (90%)

- Eliminating labor dedicated to correcting side-by-sides

- Reducing high rates of mis-sorts or recirculation due to side-by-sides

- Achieving singulation of products in limited floor space

- Handling a broad product range

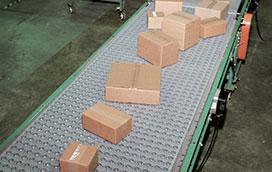

Reduce unnecessary labor costs, and improve productivity with this unique conveying solution. The ARB Singulator accurately arranges side by side products into a single file line for easy downstream running processes. It is a great solution for reducing product jams, and sorting errors that are often caused by side by side conveyed items.

ARB Singulator Features:

- Eliminates labor costs associated with monitoring and correcting side-by-sides

- Singulate product in a smaller footprint (typically 18 ft.–36 ft. / 5.5 m–11 m) than other singulation systems

- Singulate a wide variety of package sizes (as small as 4 in. x 4 in. [100 mm x 100 mm] with no maximum) and types (corrugated, shrink-wrapped, litho-packs, flats, and more)

- Reduces product damage—no guard rails or plows, and no product tumbling

- Provides continuous singulation without frequent conveyor stops/starts

Applications:

- Singulating cases within a Pallet Layer Descrambler

- Unscrambling items after bulk receiving

- Descrambling packaged food items after a spiral freezer discharge

- Singulating cases prior to palletizing, merging, sorting, scanning, and labeling

- Unscrambling side-by-side cartons from accumulation areas or uncontrolled merges

- Separating items in manual postal or parcel applications