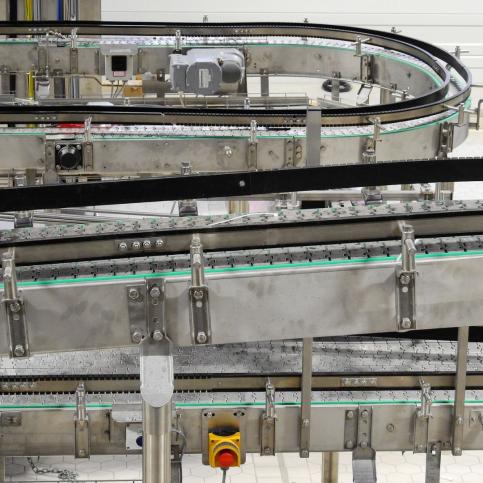

Conveyor machines are integral to efficient material handling across multiple industries. However, with conventional conveyors, spatial constraints are a significant issue. In order to tackle this logistical problem, many enterprises use low-profile conveyors. Characterized by their short height from top to bottom of the conveyor, they can be applied in conditions where spatial constraints are an essential factor. The myriad benefits, applications, and few models of these low-profile conveyors will be examined below.

Benefits and applications of low-profile conveyors

Benefits of Low-profile conveyors

Ideal for compact spaces and limited clearances

Due to its short profile and compact nature, it saves a lot of space, being a valuable addition to any material handling solution. Moreover, it is also easy to navigate above or under it. Hence, it is perfect for solutions where minimal clearance is a major deciding factor.

Judicious use of space

A busy warehouse where other machinery and workers are moving around can create major challenges when it comes to installing a conveyor system. However, with low-profile conveyors, the minimal amount of space can be used judiciously without compromising on material handling. Simultaneously, there is plenty of room for other equipment and personnel to perform their tasks without compromising on safety.

Economical

A quality low-profile conveyor is not only easy to install, but it also requires minimal upkeep. This translates to fewer repairs and more cost savings in the long run for the warehouse/facility using these conveyors.

Built to handle fragile products

Lastly, low-profile conveyors can effectively handle fragile unit loads and transport them across large distances. Hence, multiple industries can utilize these conveyors to their desired effect.

Applications:

Packaging

As mentioned above, due to their compact nature, they are a perfect fit for the packaging industry, as they can be integrated with other equipment such as labelling or marking devices.

Material Handling

Many material handling companies employ a lot of complex equipment along with conveyors such as sorters and forklifts. Low-profile conveyors can easily be installed above or beyond this equipment, saving space as well as not disturbing the workflow.

Pharmaceutical

The pharmaceutical industry requires a fair bit of assembling starting from sorting the pills to labelling bottles and so on. Fortunately, low-profile conveyors can be used to handle these delicate products with care. Moreover, they can also navigate tight corners and spaces. Therefore, low-profile conveyors can balance spatial constraints with a high throughput with ease.

Norpak’s Range of Low-profile conveyors:

Norpak Handling offers its own range of low-profile conveyors. Here are the salient features of 3 such models:

Low Profile Belt Conveyor

- Can handle a maximum load of 450 lbs

- Versatile belt width ranges starting from 2” to 24”

- Snap-in sealed tail assembly makes conveyor belt replacement very simple

Cleated Conveyor

- High-tensile cleats built to handle products in tight spaces

- Cleats have a high strength-to-weight ratio and are securely welded onto the surface

- Maximum operating speed of 225 fpm

Magnetic Conveyor

- Uses ceramic magnets to create an optimal magnetic field that can move products with ease

- Laser cut, 10 gauge, stainless steel body

Conclusion

To know more about the different conveyor systems that can boost your business operations, reach out to us at Norpak Handling. We have been providing businesses throughout Canada with top-of-the-line conveyor belts and conveyor equipment for decades. Get in touch with our Systems Applications Engineers today to learn more about how we can craft tailor-made material handling solutions specific to your business requirements.