The Difference Between Rollers Set Low And Rollers Set High On A Conveyor

When it comes to material handling solutions, the case for Hytrol parts and roller conveyors, such as Hytrol’s NBEZ, NBEZ-A, NBLR, and ABLR, sits undisputed for the accumulation and transportation of products.

Roller conveyors continue to make headway across production lines, thanks in no small part to the choice in frame stylings: rollers set high (RSH), and rollers set low (RSL).

Don’t be thrown awry by these distinctions, they simply refer to the rollers’ position in vertical space in relation to the side frame. While RSH conveyors may be more familiar to you, thanks to their prominence, we’ll be shedding a light on the setup, Hytrol parts, and advantages of both frame types to give you a more rounded view on their individual strengths.

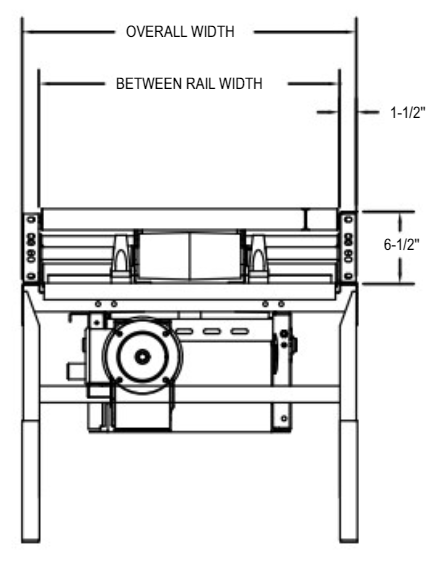

The RSH Setup

RSH conveyors are typically manufactured to have 6-½” tall side frames with 1.9” diameter tread rollers, as demonstrated by the section “x-x” view of Hytrol’s ABLR below:

RSH frame designs are named as such due to the peak of the roller being ¼” higher vertically than the top of the side frame.

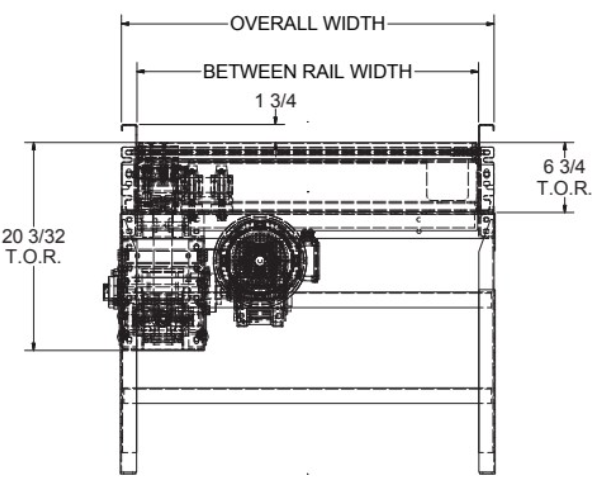

The RSL Setup

Side frames for this configuration are 2” taller (8-½” total) when compared to their RSH counterparts, all while the position of the roller is maintained at the bottom of the frame. Hytrol’s NBLR, shown below, is a perfect representation of this:

It is this taller side frame that allows the rollers to sit 1-¾” lower than the top of the frame.

When RSH Is The Right Choice

For operators reliant on pulling products from a conveyance system, RSH frame stylings can make these tasks less troublesome as they are not required to pull over the height of a built-in rail due to the rollers being positioned above the frame. What’s more, RSH stylings should be implemented for situations when diverters and transfers are used to transition a product on or off a conveyor.

Adding to this, RSH frames inherently place the load above the frame, allowing for the transport of products wider than the conveyor itself, i.e. overhang, as long as it does not feed into narrower conveyors. This is desirable for systems looking to handle a wide range of product dimensions.

When RSL Might Be Right For You

Flexible Installation and Costs

With RSL setups, the mounting of select Hytrol parts are made simpler as reflector and accumulation kits come preinstalled, this can be important for facilities looking have a tighter rein on the downtime they incur. In addition, labor costs may potentially be more flexible as installation teams need not be as scrupulous when it comes to unpacking, sorting through Hytrol parts, and assembly.

Handling and Sensing Made Easy

Products that are narrower in dimension can be notoriously troublesome for conveyance as they are prone to catch on guardrails. On top of this, without specialised installation, such as that provided by Norpak Handling, narrow products can become lodged within reflector channels and disturb product flow.

RSL conveyors can alleviate some of these concerns; with a lack of reflection or accumulation channels to become lodged into, these low set rollers provide an effective means for photoelectric sensors to detect conveyed products, especially pertinent for those of the narrow variety.

Should a guardrail be necessary for your RSL conveyor, reach out to Norpak - we have offices in Delta, BC and Port Hope, ON that can help guide you towards sourcing the right Hytrol parts.

Undisturbed Conveyance

A product transitioning between conveyance sections can present an issue – snagging.

RSL channels mitigate snagging by incorporating what are known as flow tabs on the side channels. Flow tabs can be located at the end of a conveyor frame and are pushed away from the conveyor surface to facilitate seamless product transitioning between independent sections.

When joining bed sections, it is important that floor supports be installed; Norpak, an authorised distributor of Hytrol conveyors, stock a wide selection of supports should you be looking to stock or order these specific Hytrol parts.

Norpak Handling is a leading Canadian conveyor equipment and systems solution provider, specializing in complete project integration services including maintenance and project management